Brake Disc and Brake Pad

BKR Introduction

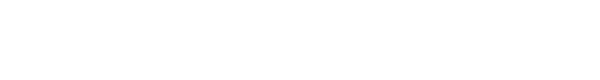

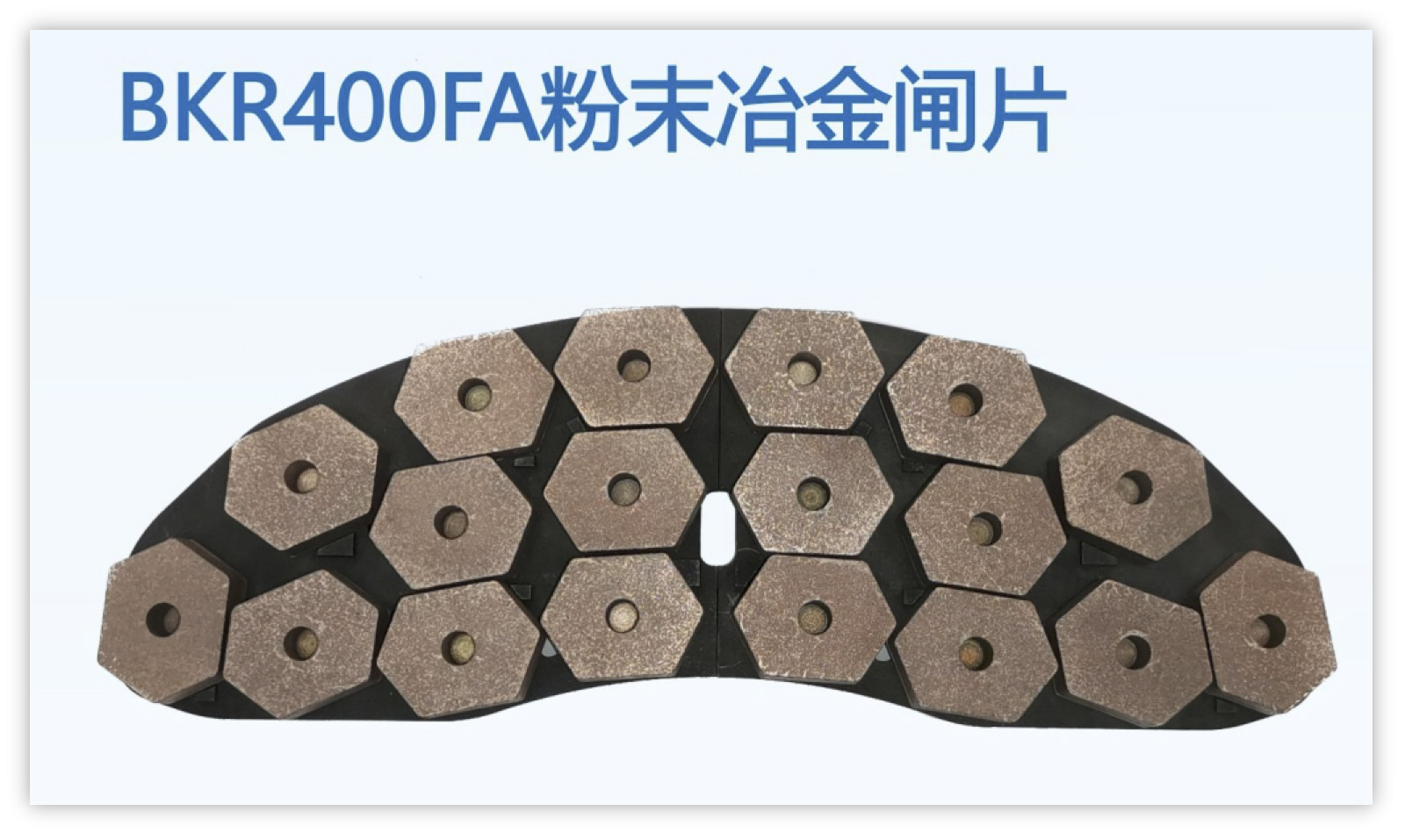

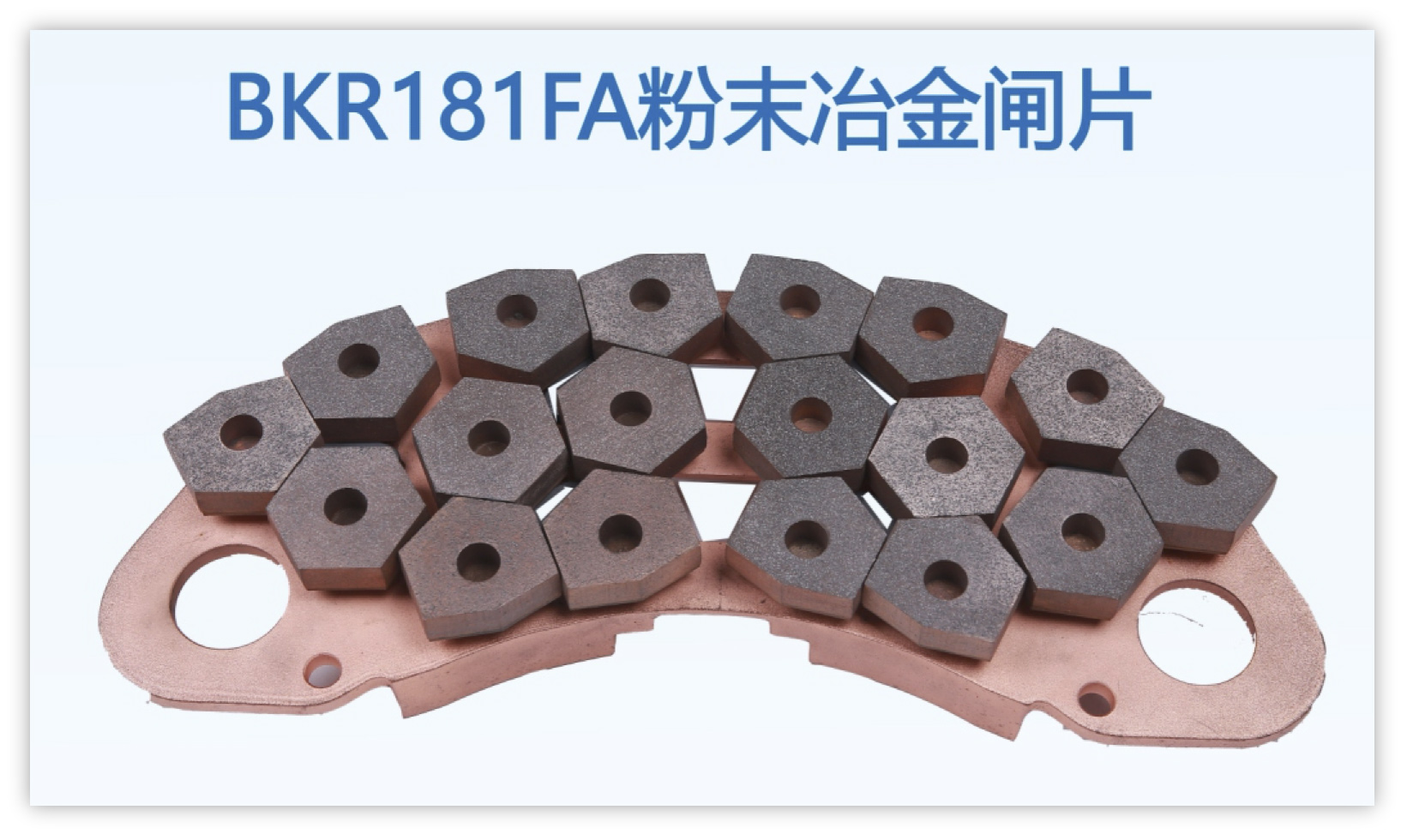

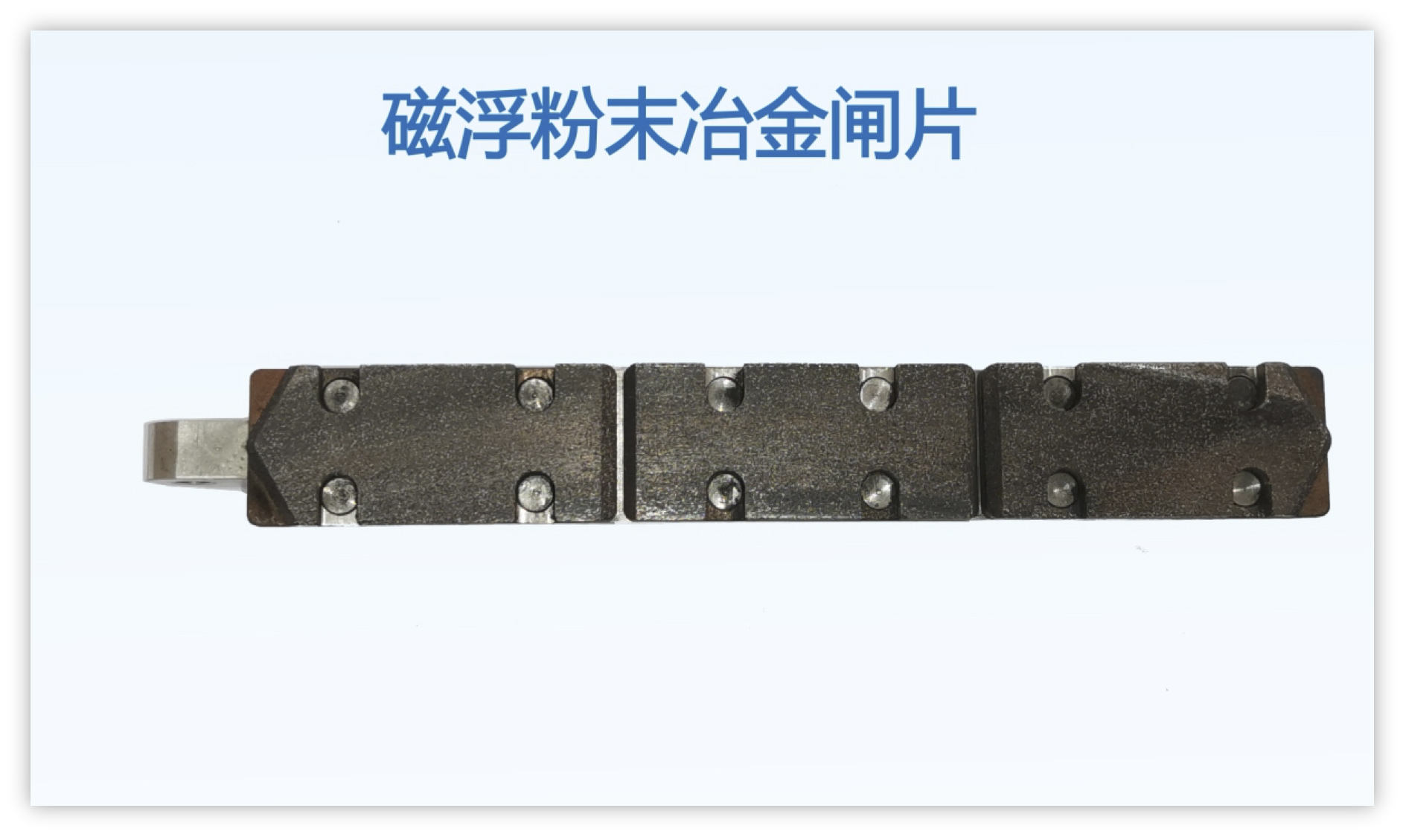

In 2021, through the acquisition of BKR, application areas of the company's brake pad product were further broadened. Located in Changsha High-Tech Development Zone, Hunan Province, BKR is a high-tech enterprise that develops, produces and delivers brake materials for high-speed trains, locomotives, metros and magnetic levitation trains and other rail transportation vehicles. The company has key core technologies such as formula design and pressurized sintering of powder metallurgy friction material, and a powder metallurgy brake pad production line with an annual capacity of over 30,000 pieces. The brake pads produced by the company have excellent performance and have been supplied to Xi'an, Chengdu, Zhengzhou, Beijing and other railway bureaus with more than 80,000 pieces without any quality problems, which has been widely recognized by the clients. The company's technology is all independently developed with completely independent intellectual property rights.

EMU BRAKE

ATD brake production lines were introduced from Akebono Brake in 2008, contains processes including counterboring, slotting, hot riveting, shaping, grinding and engraving, etc. Although the annual production of the new lines is as much as 24,000 pieces, our brake pad has never brought about a railway transportation accident. In 2014, our brake pad achieved the CRCC certification for EMU brake.